How To Measure Custom Hydraulic Hose Assemblies?

How To Measure Custom Hydraulic Hose Assemblies?

When measuring hydraulic hose assemblies, you need to consider multiple different measurements to make sure you have the right hose assembly for your application. These include ID (inner diameter), OD (outer diameter), and overall length.

Inner diameter is the diameter of the empty space inside your hose that the fluid must travel through. The OD of the hose has to do with the thickness of the hose and might be important for diverse things: like where the hose is going to fit and the power of the hose assembly. High-pressure hydraulic hoses tend to have a larger thickness as a ratio to its ID. The overall length of your hydraulic hose assembly will help you decide what sort of flow rates you can handle, along in with your ID. A smaller hose will have a higher pressure drop or an overall long length than will a larger diameter hose.

A hose should be sized correctly to handle the flow with as little pressure drop as possible because pressure drop is wasted trying to move fluid through a conduit. The total amount of pressure drop should be as minimal as possible.

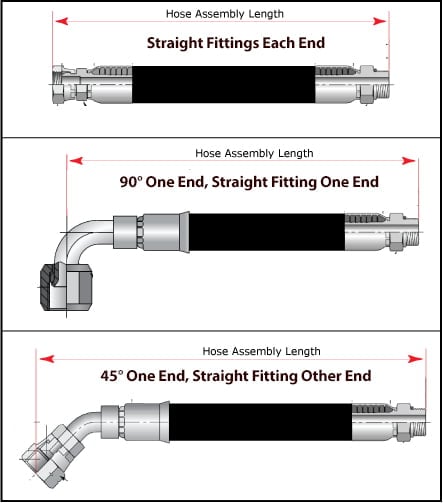

When measuring overall length, measure end to end including fittings as shown below.

Begin Creating Your Made to Order Hose Assembly for Purchase Here.